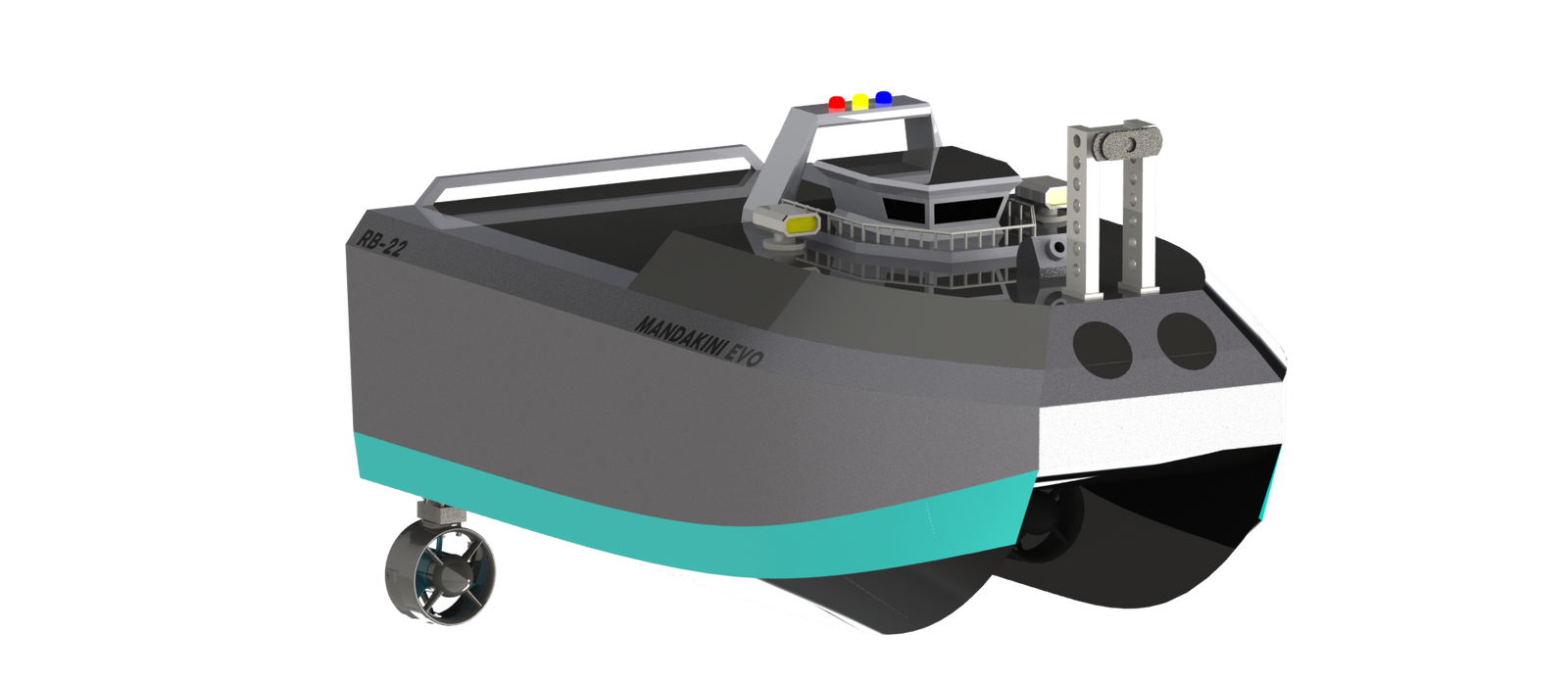

Mandakini EVO is the second ship of Bengawan UV Roboboat team that made for the International Roboboat Competition, this ship is a development of the previous ship The Mandakini NEO. We developed the ship based on our previous research with small aspects ranging from Hull, Sensor Sytem, Navigation System and Propulsion System, because we believe a big change start from a small change.

Technical Design Report

DETAIL OF HULL DESIGN

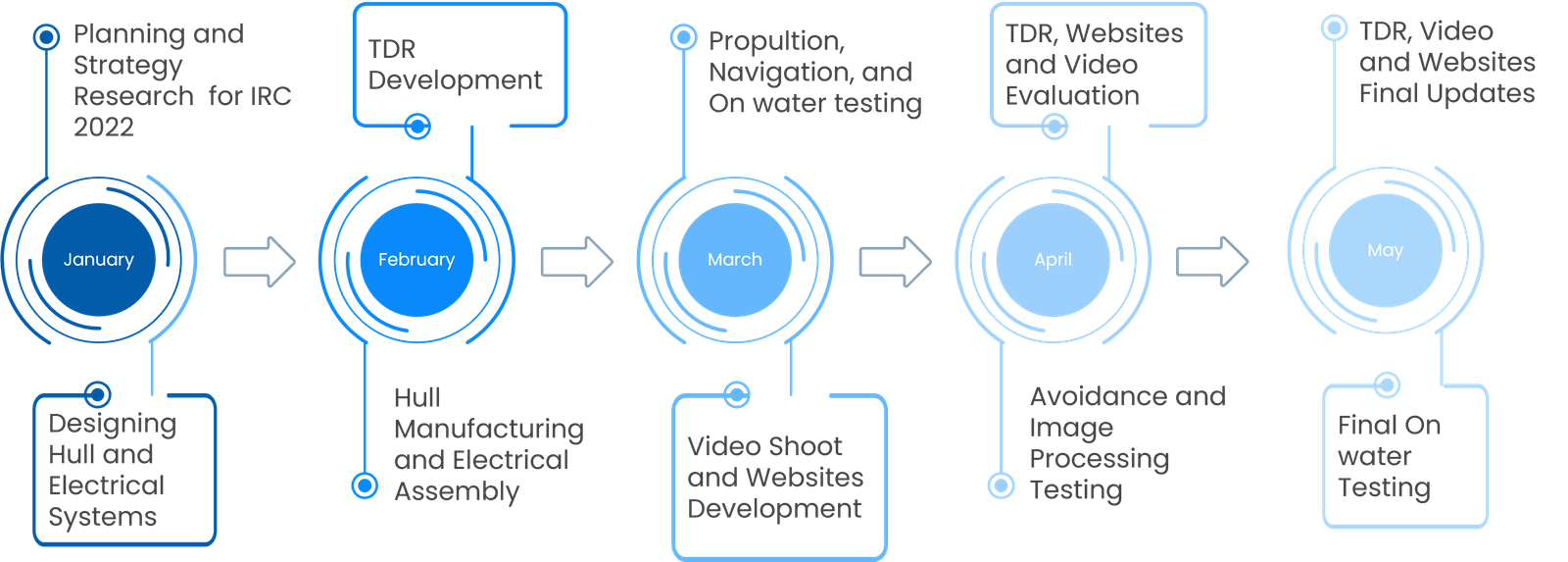

RoboBoat is an international student competition to design autonomous robotic boats. The robotic boat navigates through the challenge course with impressive maritime maneuverability. This year is the second year for Bengawan UV Roboboat team to compete in the Roboboat competition.

For More Information

In the navigation system, we use the Pixhawk PX4 as the main navigation system that will be controlled through the Mission Planner application which is used to determine the location of the ship's track so that the ship can be able to move away from each mission. The navigation system uses GPS so that the ship can precisely follow the track that has been created in the Mission Planner application. To test the navigation system of the ship, we placed five waypoints on five different coordinates. The use of five waypoint represents the number of waypoints used to complete the entire mission.

The

problem we experienced during navigation testing was that sometimes GPS is difficult

to find satellite signals and result in a lack of precision of the ship's point

point. This is because the testing site we do is in a lake that has shady trees

and blocks satellite signals. We addressed the problem by calibrating in a fairly

spacious place to get a better satellite signal.

Hull test was performed by combining software simulation. The team used Maxsurf and ANSYS software to perform Resistance, Stability and Seakeeping analysis. The Tests are performed to analyze things that may affect components on the ship. Then we compared the data results of the Mandakini EVO (IRC 2022) with the previous ship, the Mandakini NEO (IRC 2021)

Mandakini EVO which is a developed version of Mandakini NEO. There was an 11% decrease in resistance. The maximum degree of the Mandakini EVO is 22.7° with the maximum GZ value is 0.017 m, while maximum degree of the Mandakini NEO is 21.8° with the maximum GZ value is 0.014 m. Those data are proof that our new ship has largest angle so that the ship will be safer and more stable for the on board electrical components. For the seakeping test, The

test was performed within the ship parameters of 4 m/s speed, 180°

(Head Seas) wave axis direction, and 0.02 m wave amplitude. The wave amplitude value and velocity of the Mandakini EVO were 0.0287 and

0.0231 m/s, respectively, whereas the Mandakini Neo exhibited values of 0.0295

m and 0.0385 m/s, respectively. The data show that the Mandakini EVO

experienced less vibration

The camera sensor is the eye of our ship. The camera will detect the color and shape of the obstacle, then the reading results will move the ship in the direction according to the command or program that has been made. The camera sensor has a very high degree of sensitivity, so it can add precision to the ship's movement when completing the mission.

At the time of the camera testing, the problem we faced was that we had difficulty determining the color code which resulted the ship not reading the buoy. The way to overcome this is to take a color sample first before testing.

Avoidance sensor is a

sensor that serves to feel the area around the ship. Avoidance sensors use

ultrasonic sensors that will emit ultrasonic

waves around the ship. The ship will avoid obstacles when the distance

of the ship with the obstacle is below one meter. With the addition of avoidance sensors, it is

expected to reduce the possibility of the ship hitting an obstacle so that the

mission can run smoothly.

Avoidance system testing has limitations on the sensor's reading point, where sometimes the ball buoy is unreadable. This is due to the small diameter of the buoy and is located on the surface of the water. Our solution is to make changes in the placement of sensors that we adjust to the height of the buoy on the surface of the water.

To test the propulsion on this ship we've done thruster test and manueverbility test. The Thruster test was performed by setting both the thrusters to maximum thrust while the

ship was attached to a digital scale. From five tests, the maximum thrust of

the ship was demonstrated to be at 7.8 kg. While the manueverbility test was performed by circling a buoy while the motor was at 85% speed. From

five consecutive tests, the average results for the turning radius were 0.35 m

(clockwise) and 0.38 m (counterclockwise). These data are proof that the ship

would be able to complete an IRC 2022 mission requiring great agility for

maneuvering

The problem we had with propulsion was the bending of the servo wire (servo's connection with the thruster) at the time we performed the sharp maneuver. We overcome this by replacing servo wire with bicycle spoke that has good strength and flexibility.