![[LOGBOOK] Integrated Semi-Azimuth Propulsion System Design for Autonomous Vessels](/images/research/electric-mechanic/propulsion-layout.webp)

Semi-Azimuth Propulsion System Design for Autonomous Vessels

Efficient and reliable propulsion is a fundamental requirement for autonomous vessels, as it directly affects maneuverability, energy efficiency, and overall system robustness. Through iterative development and field testing, the Mandakini platform has refined its propulsion architecture to achieve improved performance and reliability.

This section discusses two propulsion system configurations that have been implemented in different development phases, with a focus on explaining why the integrated semi-azimuth design offers superior performance compared to the externally mounted configuration.

1. Design Evolution Overview

Across its development stages, Mandakini has employed two main propulsion configurations:

- Integrated Semi-Azimuth Thruster with embedded hull integration

- Externally Mounted Azimuth Thruster with adjustable shaft height

Both configurations utilize the Blue Robotics T200 thruster as the primary propulsion unit. However, they differ significantly in terms of mechanical integration, load transmission, and hydrodynamic impact.

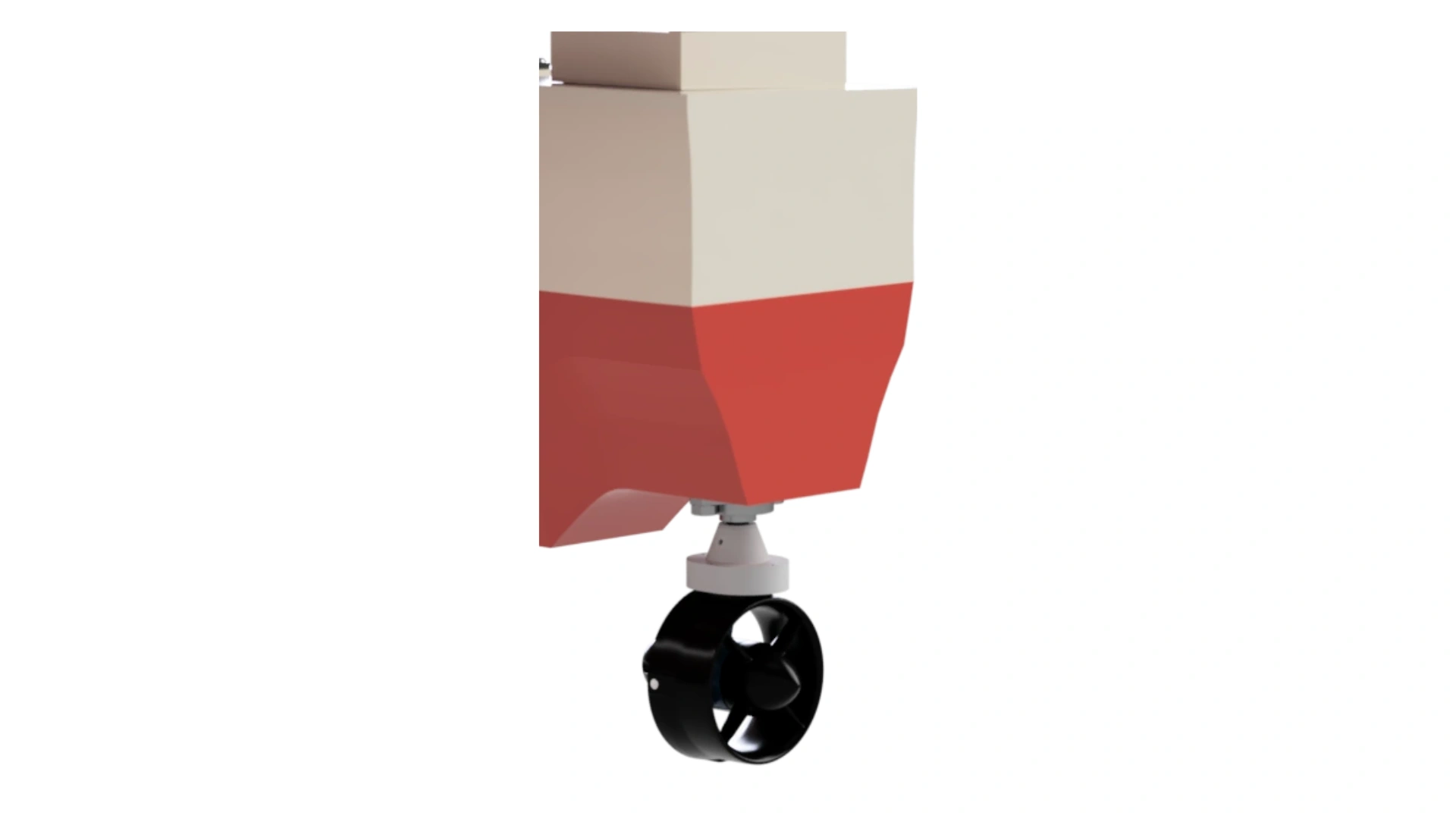

2. Integrated Semi-Azimuth Propulsion System (Mandakini Raiden)

The integrated semi-azimuth propulsion system, implemented on Mandakini Raiden, is designed with the thruster structurally embedded into the hull. Each T200 thruster is mounted on a 15 mm solid aluminum shaft that is directly integrated into the lower hull structure.

The shaft is mechanically connected to an internal servo motor, enabling controlled azimuth rotation for directional thrust while keeping all sensitive components fully enclosed within the hull.

To ensure reliability and prevent water ingress, the propulsion system adopts:

- Direct mechanical transmission between the thruster and servo motor

- A single flange bearing serving as the primary structural support

- Full internal housing of the servo and control components

The thruster is positioned close to the hull surface, reducing external protrusion and minimizing hydrodynamic disturbances.

Key characteristics of this design include:

- Low mechanical complexity with minimal moving interfaces

- Short and rigid torque transmission path

- Reduced exposure of mechanical components to water

- Improved thrust efficiency and maneuvering response

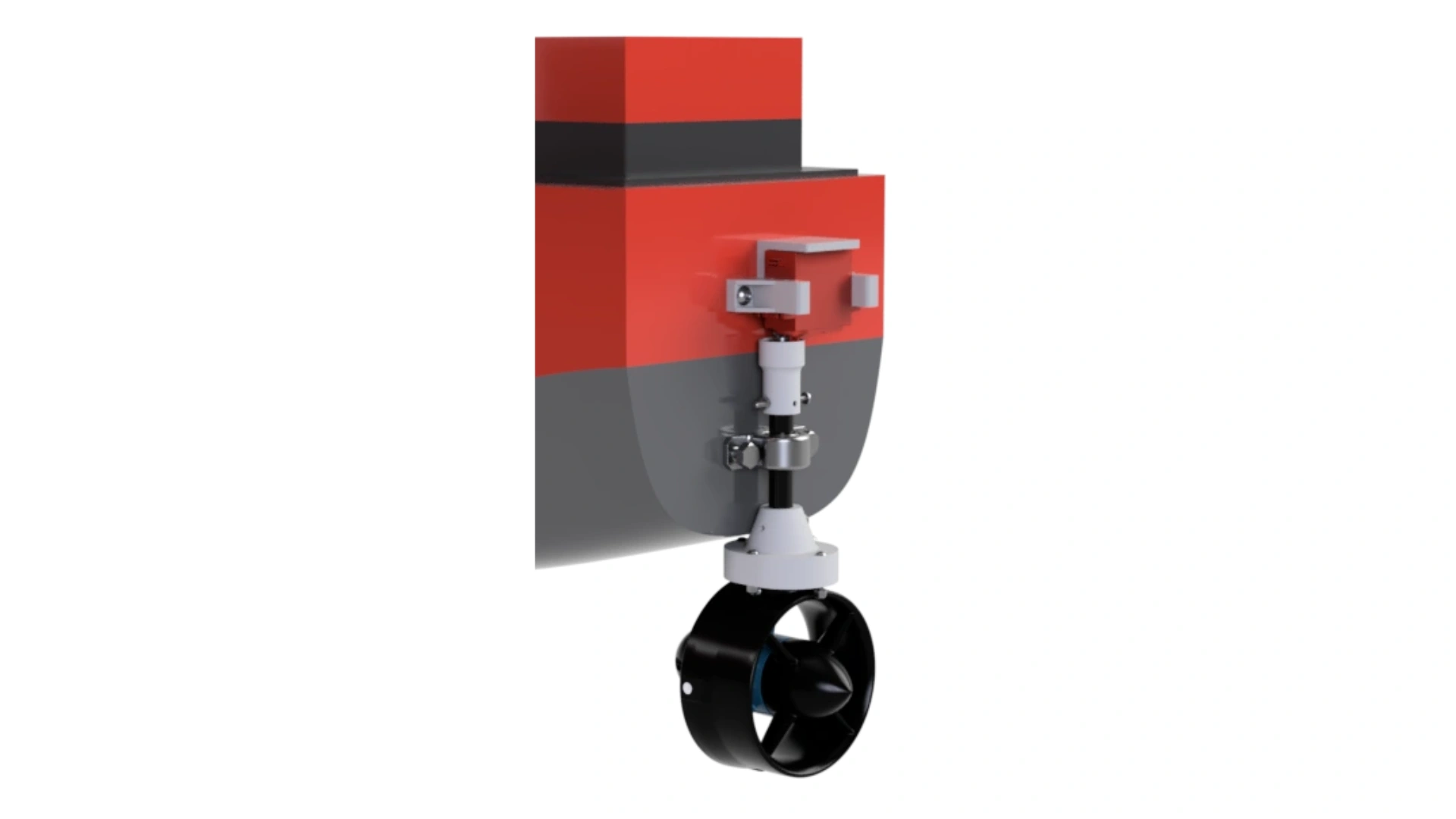

3. Externally Mounted Azimuth Propulsion System (Mandakini Zenith)

The externally mounted azimuth propulsion system, implemented on Mandakini Zenith, was developed to enhance maneuverability in constrained environments such as narrow passages and obstacle-dense areas.

In this configuration, each T200 thruster is mounted on a 15 mm hollow aluminum shaft supported by dual vertical flange bearings. The shaft height can be adjusted relative to the water surface, providing flexibility in thrust depth configuration.

Each shaft is connected to a servo motor that rotates the thruster according to motion commands generated by the Pixhawk-based control system.

Compared to earlier designs that used steel shafts and linear bearings, this configuration provides:

- Improved corrosion resistance

- Increased rigidity against wave-induced loads

- Better resistance to vibration generated by thruster rotation

However, the external mounting approach introduces additional structural and hydrodynamic trade-offs.

4. Comparative Analysis: Advantages of the Integrated Design

Although the externally mounted azimuth system offers greater adjustability, the integrated semi-azimuth propulsion design demonstrates superior overall performance for autonomous vessel applications.

4.1 Mechanical Simplicity and Reliability

The integrated design relies on a single flange bearing and a direct shaft-to-servo connection. This results in fewer mechanical interfaces, which reduces:

- Alignment sensitivity

- Bearing wear and mechanical play

- Potential points of failure

In contrast, the externally mounted system requires additional bearings and structural components, increasing mechanical complexity.

4.2 Hydrodynamic Efficiency

By integrating the thruster closely with the hull, the semi-azimuth design minimizes flow separation and drag caused by exposed mounting structures.

The externally mounted configuration introduces additional frontal area and wake disturbances, which reduce effective thrust efficiency and increase energy consumption, particularly during continuous operation.

4.3 Structural Load Distribution

In the integrated design, thrust and torque loads are transferred directly into the hull structure. This allows forces to be distributed more evenly across the vessel body rather than being concentrated on external brackets or mounts.

As a result, the system exhibits:

- Lower stress concentrations

- Reduced vibration transmission

- Improved long-term structural durability

4.4 Environmental Protection

Placing the servo motor and critical components entirely inside the hull provides superior protection against environmental exposure, including water ingress, corrosion, and mechanical impact.

Externally mounted systems, while easier to access, remain more vulnerable to harsh marine conditions.

5. Design Trade-Off Considerations

While the integrated semi-azimuth propulsion system offers higher efficiency and reliability, it provides less flexibility in adjusting thruster depth compared to the externally mounted configuration. Nevertheless, for autonomous vessels that prioritize:

- Predictable control behavior

- Energy efficiency

- Mechanical robustness and durability

the integrated approach represents a more balanced and mission-optimized solution.

Conclusion

The integrated semi-azimuth propulsion system reflects a mature and performance-oriented design strategy for autonomous vessels. By embedding the propulsion mechanism into the hull, the system achieves improved thrust efficiency, reduced mechanical complexity, and enhanced structural reliability compared to externally mounted azimuth configurations.

This design evolution supports long-term operational stability and aligns with the safety and efficiency requirements of autonomous marine platforms.

About the Author

Logbook & experiments documented by M. Faridz. Dedicated to advancing autonomous maritime systems.